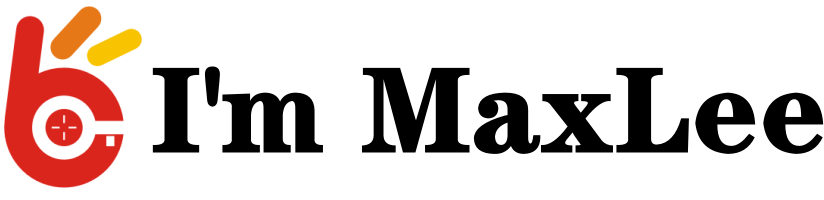

We received a consultation from a metallurgical company regarding the CEV65M-02711 model. This client's equipment is somewhat outdated and has been in operation for a considerable period.

The client's intention is clear: they hope to resolve an alternative solution. On one hand, they face cost pressures, and on the other, the product is not that easy to procure. They have two suppliers, but both are offering high prices.

Let's take a look at the product parameters.

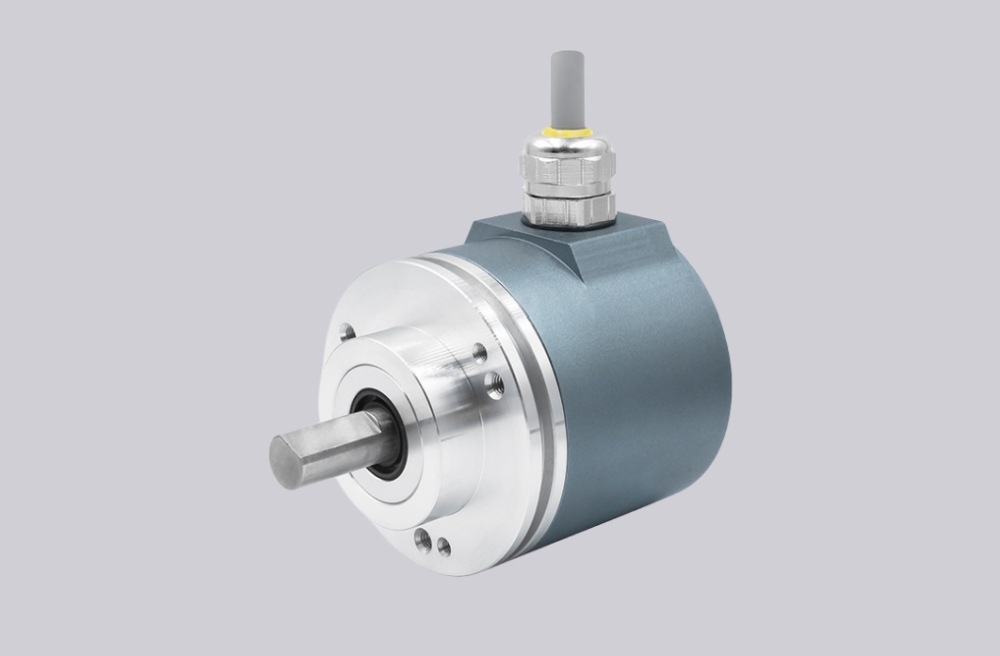

This encoder is a product with an SSI communication protocol and a resolution of 4096*4096. At first glance, this encoder seems quite ordinary. The real difference lies in the flange size, which is a 106mm flange. This flange size is relatively rare, but fortunately, we have developed similar flanges before.

The alternative solution becomes clear:

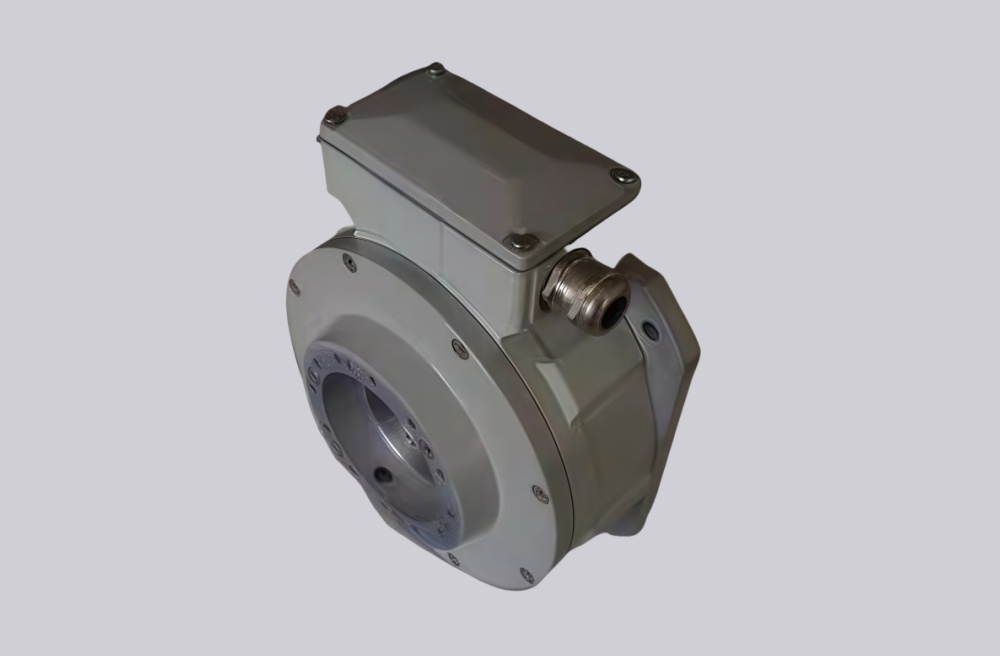

We will machine a flange according to the original size, which, combined with a 58mm aluminum alloy housing, forms a set of hardware. Of course, the 12mm solid shaft is indispensable. Then, for the internal electrical and mechanical components, we have a mature solution that can be completed with some technical adjustments.

In this way, an alternative solution is completed.

The main focus of this alternative solution is the installation size, which means the flange is the key point. We have a complete solution for the electrical part. By combining these elements, the alternative solution is achieved.

Doesn't it seem not too complicated?

In fact, we have been doing this for so long that we no longer find routine replacements challenging. This could be considered an occupational hazard; we are only interested in the more difficult parts. Therefore, the notes we write might sometimes be unclear to others. However, this is not an issue as long as we can solve the actual replacement problems.

If you need assistance, please feel free to email us.