اليوم، دعونا نناقش حلاً بديلاً لأجهزة التشفير TWK، مع التركيز بشكل خاص على النموذج: CRD58-8192R4096C2Z01.

ينشأ هذا الموضوع من صعوبات شراء موديلات سلسلة TWK CRD58، والتي قد لا تمثل مشكلة في بلدان أخرى ولكنها تمثل تحديًا بالفعل في الصين. تواجه العديد من شركات الصلب والألومنيوم تحديات كبيرة عند شراء هذه المشفرات.

وبصفتنا مزود خدمة تشفير، فقد عهدت إلينا العديد من شركات المعادن بتصنيع منتجات تشفير بديلة تتناسب مع هذا الطراز المحدد، وإذا كانت لديك نفس الاحتياجات، يمكنك التواصل مع المدون، ويسعدنا تقديم المساعدة.

أولاً، دعنا نلقي نظرة على مقدمة المنتج الخاص بتشفير TWK هذا.

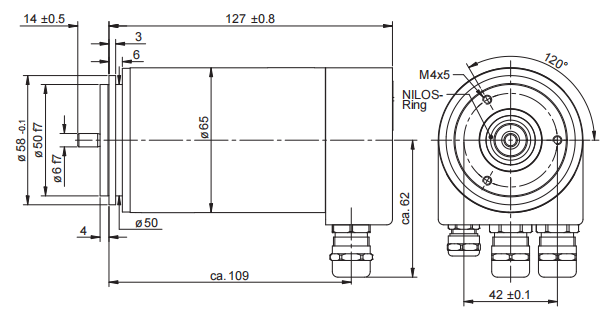

هذا المشفر مزود ببروتوكول اتصال Profibus-DP، ويتميز بقطر خارجي يبلغ 58 مم.

كما هو موضح في الرسم البياني، فإن أداة التشفير TWK هذه لها قطر تركيب خارجي يبلغ 58 مم وعمود بحجم 6 مم.

الدقة: 8192 موضع دوران، كحد أقصى.

نطاق القياس: 4096 دورة

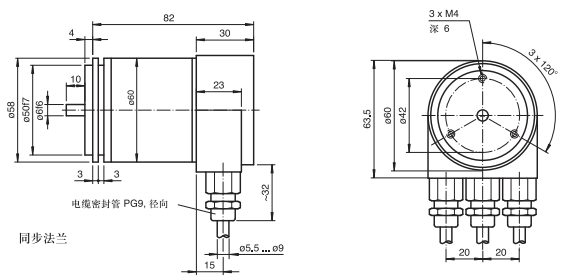

توضح الصورة التالية الحل البديل الذي قدمناه.

تحافظ أداة التشفير البديلة الخاصة بنا على نفس أبعاد التركيب والمعايير الوظيفية مع تقليل الطول الكلي لأداة التشفير. تم اختبار أداة التشفير هذه على نطاق واسع في المنشآت المعدنية وأثبتت دقة وثبات ممتازين.

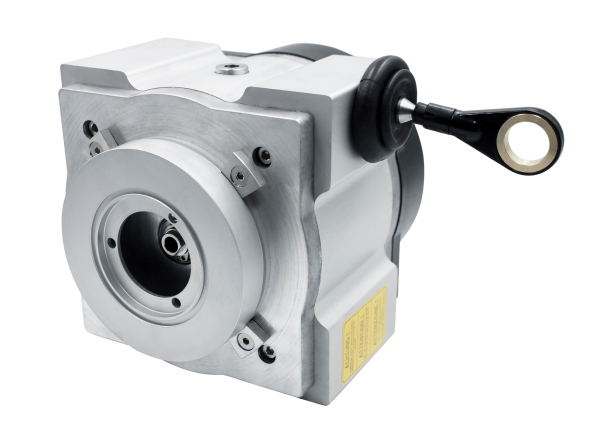

لهذا الغرض، نوفر أيضًا صندوق مستشعر سحب الكابلات المطابق مع نطاقات قياس 2 م، 3 م، 5 م، 10 م، وأكثر من ذلك.

تُستخدم لقياس الكابلات في أنظمة الجر المزودة بشفاه مؤازرة بعمود 6 مم أو شفاه تثبيت العمود 10 مم.

عند هذه النقطة، يمكن لمنتجنا أن يحل بسلاسة محل جهاز الاستشعار TWK Seilzugsensor بالكامل. لقد حقق نتائج ممتازة في التطبيقات العملية، خاصةً في البيئة الفعالة من حيث التكلفة السائدة في الصين، مما يجعله مفضلاً للغاية من قبل عملائنا.